Lithium battery temperature sensor selection and arrangement

July 28 , 20231.NTC Thermistor Selection points

The following nine factors should be considered when using an NTC thermistor to collect the temperature inside a lithium power lithium battery module:

1.1 NTC Thermal Housing

The case of NTC thermistor should be smooth, uniform color, no cracks, no deformation, no serious scratches, and the color of each batch of products (including lead wires) should be consistent without any corrosion.

1.2 Temperature range

NTC thermistors are made of different materials according to the operating temperature of the application.NTC thermistors are generally composed of temperature sensing head (metal or plastic case), terminals, wires, connectors, epoxy resin, and other filler materials.

1.3 Accuracy (within 2°C)

The NTC thermistor has good linearity and characteristics that match the entire parameter range over the entire temperature detection range, while also considering the effect of 3 points on the temperature detection accuracy:

- Resistance accuracy - B constant accuracy - Thermal diffusion constant C.

Accuracy is an important performance indicator, related to the measurement accuracy of the entire measurement system, is very important, and therefore the higher the accuracy of the price is also more expensive.

Factors that determine the accuracy of NTC thermistors:

1. Errors in itself;

2. The smaller the error in resistance and B value, the higher the precision;

3. The way the temperature sensing head contacts the temperature measurement object.

Direct contact is more accurate than indirect contact, and because the R-T curve of the NTC thermistor is nonlinear, it is impossible to guarantee the same accuracy over a wide range of operating temperatures.

Therefore, to have high measurement accuracy, the center working temperature point of the workplace should be selected. Because the farther away from the center working temperature point, the greater the accuracy error of the temperature point.

1.4 NTC Thermistor Response Speed

In the measurement process NTC thermistor response speed is fast, to reach the closest temperature time to not more than 10 seconds, otherwise in the practicality of the efficiency requirements. Different application environments require different response speeds, and different materials also have different thermal conductivity.

NTC Thermistor Response Speed Influencing Factors.

1, the chip's thermal time constant: the smaller the constant, the faster the response;

2, the thermal conductivity of the temperature-sensitive head shell material: the higher the coefficient of thermal conductivity performance is more excellent;

3, the size of the temperature-sensitive head size: the smaller the size of the heat conduction time is shorter, the faster the reaction speed;

4, the temperature sensing head filled with thermal conductive gel: temperature sensing head filled with high thermal conductivity of the thermal conductivity of the silicone grease, will be faster than not filled or filled with low thermal conductivity of the thermal conductivity of the silicone grease reaction speed.

1.5 Self-heating

Within a certain range, the selected value of the resistor should take into account its self-heating, otherwise its self-heating will affect the temperature measurement. At the same time, the NTC thermistor should have very good reliability, i.e., still superior performance in the face of cold and thermal shocks, small thermal time constant and fast response speed.

1.6 Stability

Stability is the ability of NTC thermistor to keep its performance unchanged for a long period of time after use. In addition to the stability and reliability of the chip, the sensor itself and the structure of the factors affecting long-term stability, there is also the environment in which it is used.NTC thermistor has excellent stability, it must have excellent environmental adaptability.

Elements of NTC thermistor stability selection:

1. Use reliable NTC thermistor.

2、Select the structure of reasonable NTC thermistor, and have strong mechanical strength.

3、Aiming at different use scenarios, choose different filling materials.

1.7 Lifespan

Not less than 6 years (including 2 years for storage).

1.8 Environmental shock states

The NTC temperature sensor should be free from mechanical damage and any loosening after 3 shocks in -55℃ to 70℃ environment.

1.9 Insulation resistance

Greater than 10M/500V.

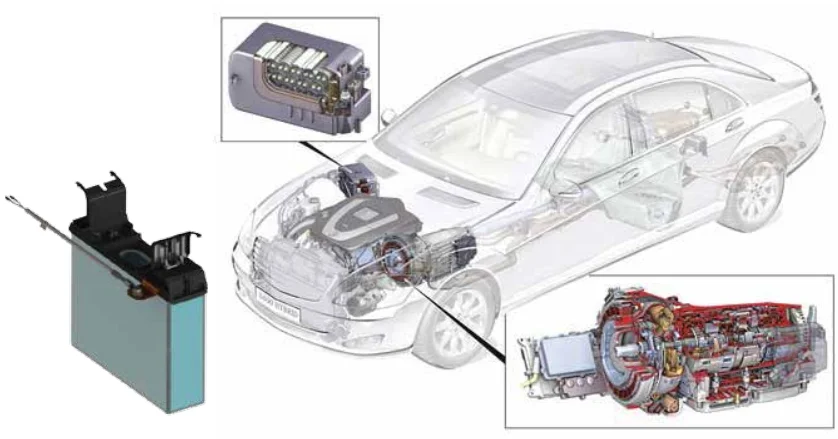

2、NTC thermistor arrangement

Power lithium battery module consists of multiple cells, the temperature of the cell is uniform during normal operation, while in the event of an abnormal situation, the temperature of different power lithium battery module cells will have a large temperature difference. Monitoring the temperature of the entire power lithium battery module is usually realized with 3 to 4 collection points. After the collected temperature data is input into the management unit, the temperature of the entire power lithium battery module management unit is deduced by the management unit, and the methods of temperature collection used in the design of the power lithium battery module temperature collection points are:

2.1 Direct acquisition of core temperature

The NTC thermistor is arranged on the surface of the module core. When the characteristics of the power lithium battery module core are relatively uniform, a paste method is adopted for arranging the NTC thermistor on the surface of the module core.

2.2 Indirect through-collector core temperature

At the two end plates of the module, NTC thermistors are embedded in the end plates, which can accurately sense the temperature of the head and tail of the two pieces of power lithium battery cells. According to the collected temperature to deduce the temperature of the whole power lithium battery module core, which is also a more typical approach.

2.3 Capture the temperature at the upper end of the interconnection board of the power lithium battery cell

The NTC thermistor is embedded into the internal interconnection board of the battery cell to accurately sense the maximum temperature of the power lithium battery cell.

2.4 Collect power lithium battery module bus temperature

A recess is provided in the power lithium battery module busbar, the temperature sensor is fixed in said recess, and a fixing adhesive for fixing the temperature sensor is provided in the recess.

2.5 Collect the temperature of the cover plate surface of the power lithium battery module

Paste the NTC thermistor directly on the cover plate of the power lithium battery module. When connecting the NTC thermistor to the power lithium battery busbar row and core interconnection board or bonding it to the power lithium battery module core surface or cover plate surface, consider the effect of the operation process on the NTC thermistor. Improper operation during the fixing process may result in broken wires, short circuits, or breakage of the lead coating.