Why Negative Temperature Coefficient Thermistors Dominate 2026 Temperature Sensing

Introduction

The global demand for precise temperature measurement continues to rise across sectors like automotive, home appliances, HVAC, EV battery systems, and industrial automation. At the heart of this growth is the negative temperature coefficient thermistor, or NTC thermistor — one of the most common and reliable thermistor sensor types used today.

In 2026, industry analysts show that more than 62% of compact thermal-sensing applications use NTC technology. This applies to both consumer electronics and cars — thanks to its accuracy, low cost, and fast response time.

For buyers in the U.S., Europe, and busy manufacturing areas, NTC thermistors are the top choice when accuracy and stability matter.

As a manufacturer for OEM and ODM buyers around the world, Focusens specializes in advanced thermistor solutions. We offer miniature SMD NTC chips, epoxy bead thermistors, and custom probe assemblies — designed for electric vehicles, heat pumps, medical devices, and industrial systems.

What Is a Negative Temperature Coefficient Thermistor?

A negative temperature coefficient thermistor is a temperature-sensitive resistor whose resistance decreases as temperature rises. This predictable and repeatable behavior allows highly accurate temperature measurement.

Most NTC thermistors are made from metal oxide ceramics — such as manganese, nickel, cobalt, or copper oxides. These materials are engineered to provide a strong response to temperature changes.

Key Advantages of NTC Thermistors

- High accuracy (typically ±0.1 °C to ±0.3 °C, depending on type)

- Fast response time (5–200 ms depending on structure)

- Low cost compared to RTDs and thermocouples

- Excellent long-term stability

- Compact form factor, suitable for tight or miniaturized installations

How NTC Thermistors Work

At the core of every negative temperature coefficient thermistor is the relation between temperature and electrical resistance: as temperature increases, the semiconductor material allows more electrons to move freely — resulting in lower resistance.

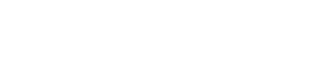

The Resistance–Temperature Curve

NTC thermistors follow an exponential curve: resistance drops rapidly in certain temperature ranges. This non-linear behavior gives them extremely high sensitivity within their specified operating range.

2025 Market Trends for NTC Thermistors

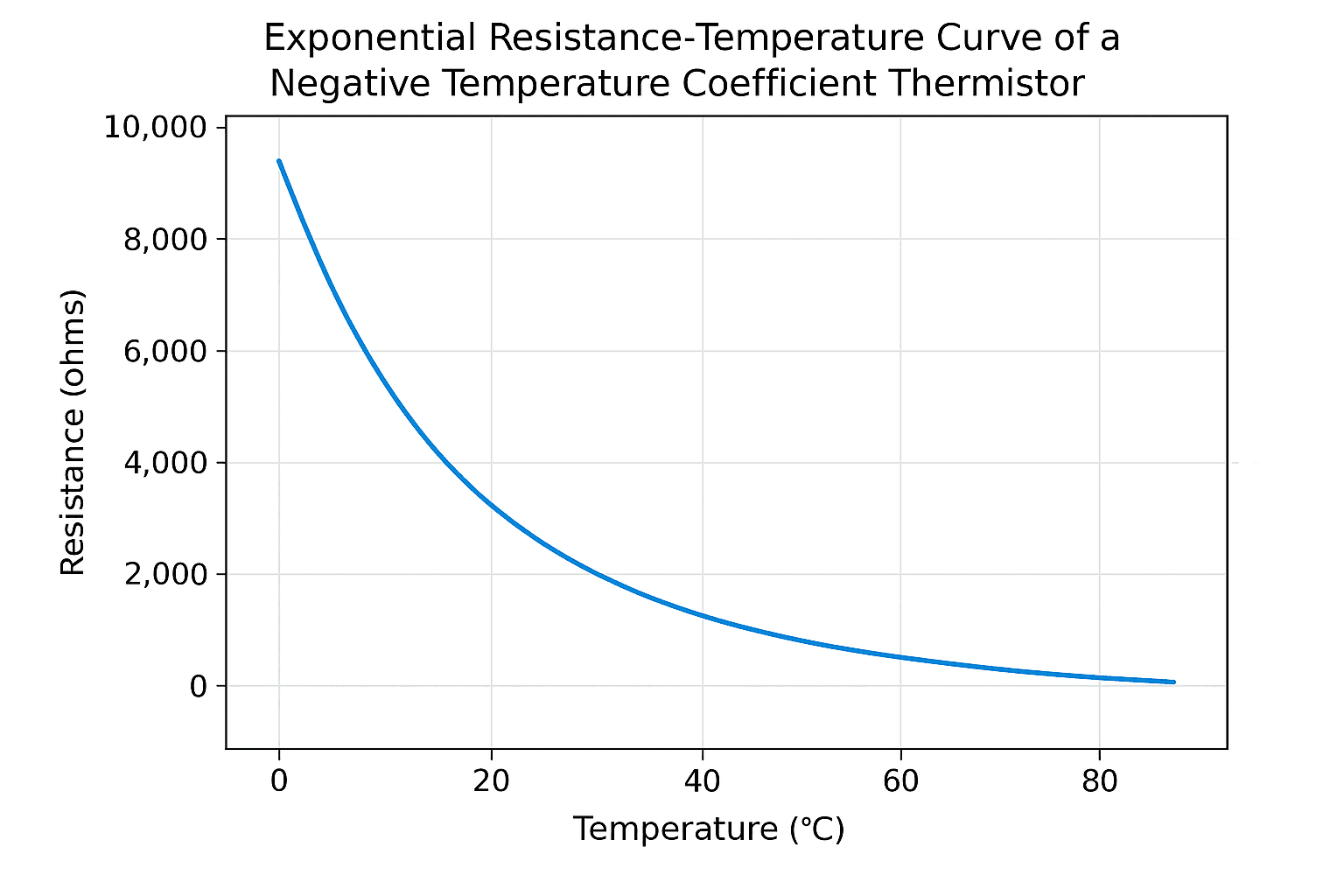

Forecasts for 2025 predict that NTC thermistors will reach $5.8 billion USD in global market value. This growth is driven by:

- EV battery thermal management

- Heat pump expansion in Europe and the U.S.

- Smart home and smart appliance adoption

- Industrial automation and robotics

- Medical devices and patient-monitoring systems

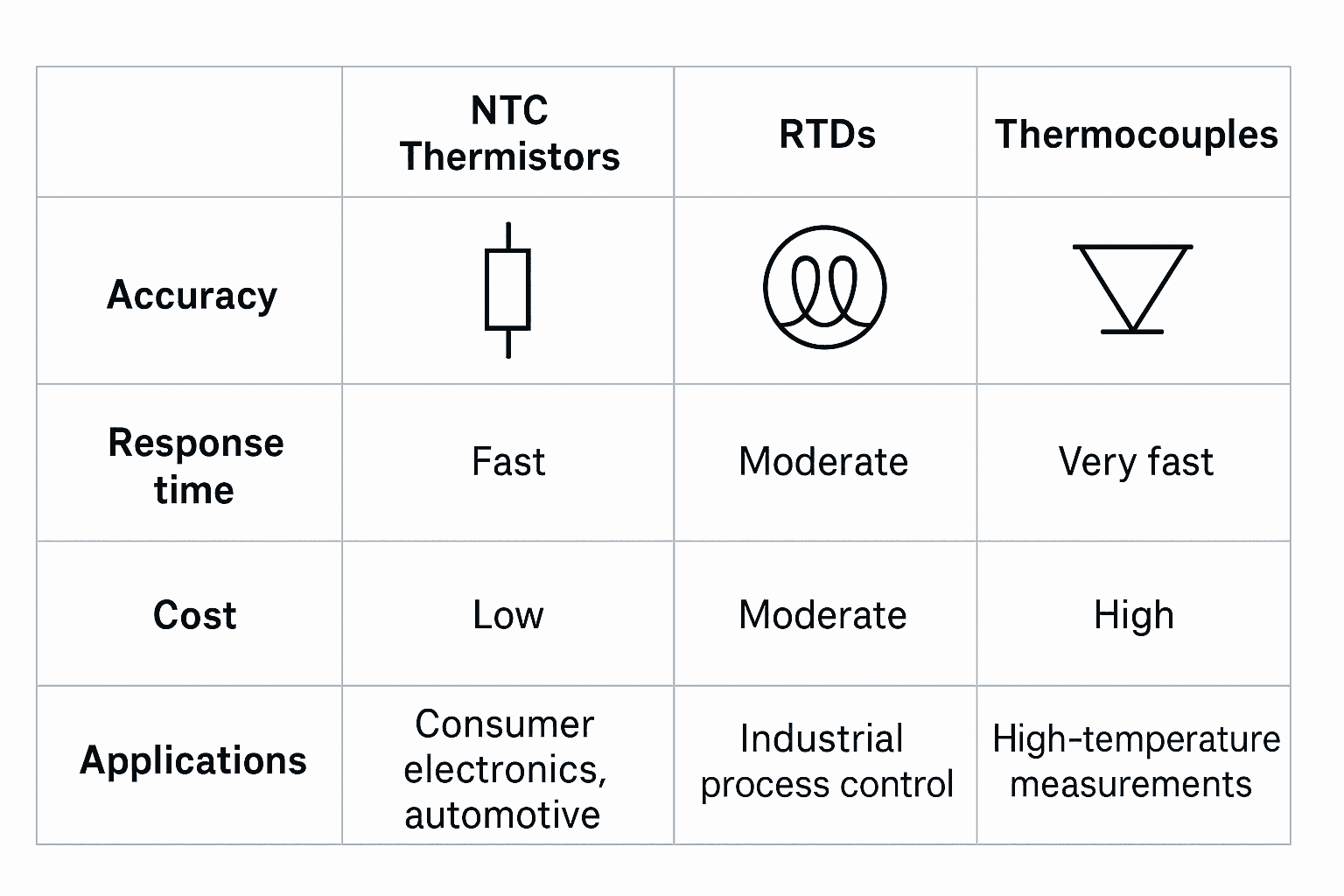

NTC vs. Other Temperature Sensors

| Sensor Type | Accuracy | Response Time | Cost | Best Use |

|---|---|---|---|---|

| NTC Thermistor | High | Extremely fast | Low | Consumer electronics, HVAC, EV batteries, compact devices |

| RTD (e.g. PT100 / PT1000) | Extremely high | Moderate | Higher | Industrial, lab, critical-precision environments |

| Thermocouple | Medium | Fast | Low | High-temperature industrial applications (> 600 °C) |

Where NTC Thermistors Are Used

- Automotive & EV Systems — essential in battery packs, coolant loops, cabin-temperature sensors, onboard chargers; fast response meets strict EV safety requirements in U.S. and European markets.

- HVAC and Heat Pumps — rising heat-pump adoption increases demand for accurate air / refrigerant temperature sensing.

- Consumer Electronics — phones, wearables, PCs, chargers rely on thermistor sensors to prevent overheating and manage thermal loads.

- Industrial Equipment — automation systems often use NTC probe assemblies for monitoring temperatures of motors, transformers, PCB assemblies, bearings, or process-control instrumentation.

Why Global Buyers Choose Focusens NTC Thermistors

At Focusens, we produce millions of thermistors and temperature probes annually for clients in the U.S., Germany, Italy, Spain, Korea, and more. Our strengths include:

- High-precision NTC chips with tight tolerances (±0.1 °C available)

- Customizable probe structures: stainless steel, brass, epoxy, ceramic

- EV-grade sensor design experience

- Rapid prototyping & engineering support

- Automotive-standard quality certification (IATF 16949)

We also support custom B-value matching, long-lead cable assemblies, waterproof sealing, and connectors tailored to your device.

How to Select the Right NTC Thermistor

When selecting an NTC thermistor sensor, consider the following criteria:

- Temperature Range — Ensure the thermistor’s operating range matches your environmental conditions.

- Accuracy Requirements — Tight tolerances are essential for EV battery systems, medical devices, or any critical monitoring systems.

- Response Time — For fluid or surface measurements, choose structures with faster response.

- Packaging Type — Bead, SMD, epoxy, or probe packaging affects durability, response speed, and waterproof performance.

- Application Standards — Check compliance with required standards (e.g. UL, automotive, medical) as needed.

FAQs

What is a negative temperature coefficient thermistor used for?

NTC thermistor (thermistor sensor) is used wherever fast, accurate temperature monitoring is needed — such as in EV batteries, HVAC systems, appliances, consumer electronics, and industrial equipment.

Are NTC thermistors more accurate than thermocouples?

Yes. NTC thermistors deliver higher accuracy and faster response within common temperature ranges. Thermocouples are more suitable for extreme high-temperature environments (> 600 °C).

Can Focusens customize the NTC probe structure?

Yes. Focusens offers full customization: cables, housings, connectors, chip specs, and probe designs for fluids, gases, or surfaces.

Conclusion

Understanding the role and advantages of a negative temperature coefficient thermistor (NTC thermistor) is crucial when selecting the right thermistor sensor. Their high accuracy, fast response, low cost, and versatility make them ideal for many modern applications — from EVs and HVAC to consumer electronics and industrial automation.

If you need reliable, high-precision, and customizable NTC solutions, Focusens is ready to support your project. Leave an inquiry and our engineering team will help you select the ideal NTC thermistor for your application.

+86-551-69109668

+86-551-69109668